In today’s global market, the call for sustainable manufacturing is louder than ever. Export companies across the agri-processing industry are increasingly adopting high-efficiency hydraulic oil press machines as a strategic move to raise production output while fulfilling environmental responsibilities.

The intensifying focus on green production solutions stems from tightening international environmental standards and buyers’ demand for eco-friendly products. Companies that operate in the oil extraction sector face the dual pressure of maximizing yield and minimizing ecological impact. High-efficiency hydraulic oil presses emerge as an optimal answer, combining advanced technology with resource-conscious operations.

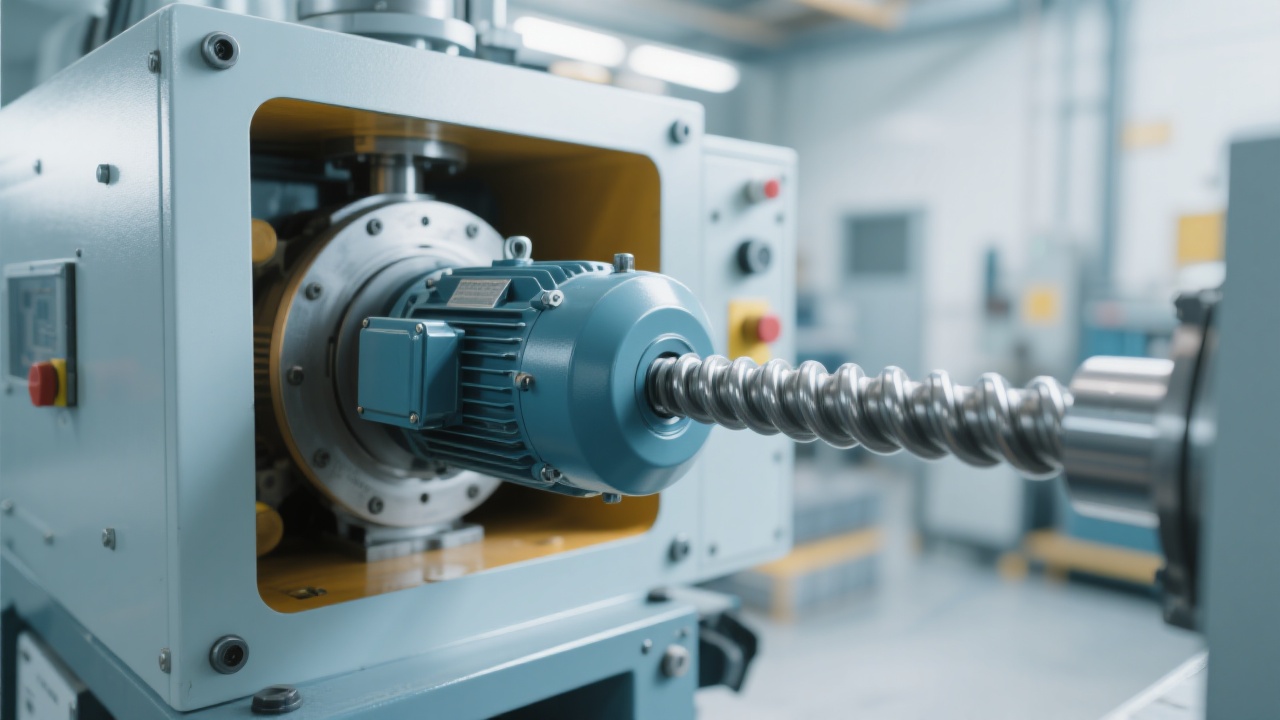

Unlike traditional screw presses, these hydraulic machines apply stable, high-pressure output to a broad range of oil-bearing materials—from soybean and sunflower seeds to walnuts and peanuts. This pressure consistency supports an average oil recovery rate exceeding 98%, outperforming typical mechanical presses that often hover around 90-92%. The latest models integrate fully automatic control systems, minimizing manual intervention and reducing operator errors.

| Feature | Benefit | Impact |

|---|---|---|

| Stable hydraulic pressure | Consistent high oil extraction rate | Increases yield by up to 8% |

| Fully automated control system | Simplifies operation and reduces workforce cost | Cuts labor expenses by approx. 25% |

| Energy-efficient hydraulics | Lowers power consumption significantly | Saves up to 20% energy compared to traditional presses |

Meeting and exceeding environmental regulations—such as the EU Emission Standards and EPA guidelines—is critical for exporters targeting global markets. High-efficiency hydraulic oil presses embody these standards by:

A recent independent audit from a leading European buyer indicated a 35% reduction in waste and a 30% improvement in energy efficiency across factories deploying such equipment. These figures highlight how the technology supports both sustainability and profitability.

Consider a mid-sized exporter specializing in cold-pressed walnut oil. After installing a high-efficiency hydraulic oil press, their extraction yield rose from 89% to 97%, cutting raw material costs by over $50,000 annually. Additionally, their reported carbon emissions declined by 18%, helping them secure contracts with environmentally-conscious retailers in North America.

Another case involves a large-scale soybean oil producer in South America. Post-revamp, they observed a 22% reduction in power usage and streamlined their labor force with automated controls—translating into a 15% drop in operating expenses within the first year.

For forward-thinking exporters, adopting high-efficiency hydraulic oil presses is a strategic investment that delivers measurable improvements in throughput, cuts operational costs, and aligns production with international sustainability mandates. The technology leverages industry-leading features to ensure consistency, safety, and environmental stewardship.

This comprehensive solution empowers enterprises to differentiate themselves in competitive markets while supporting global ecological goals.

Exporters wishing to boost competitiveness and green credentials should explore the tangible benefits of these hydraulic presses. Dedicated product demonstrations and customized consultations are available to showcase how this technology aligns with unique production demands.

Discover How High-Efficiency Hydraulic Oil Presses Can Elevate Your Production Today