We've found that in the vegetable oil pressing industry, the temperature control system plays a pivotal role. It directly impacts the oil yield, oil quality, and the stability of the equipment. For instance, a precise temperature control with an accuracy of ±1℃ can improve the oil clarity by 23% compared to a less precise control of ±5℃. Different climate regions, such as the hot - humid tropics in Southeast Asia and the dry - hot deserts in the Middle East, present unique challenges to temperature control.

In tropical regions like Southeast Asia, the high humidity and temperature can cause issues such as moisture absorption in the raw materials, which affects the pre - heating process. In contrast, the dry and hot climate in the Middle East may lead to over - heating problems and faster wear of the equipment. These environmental differences require distinct temperature control strategies.

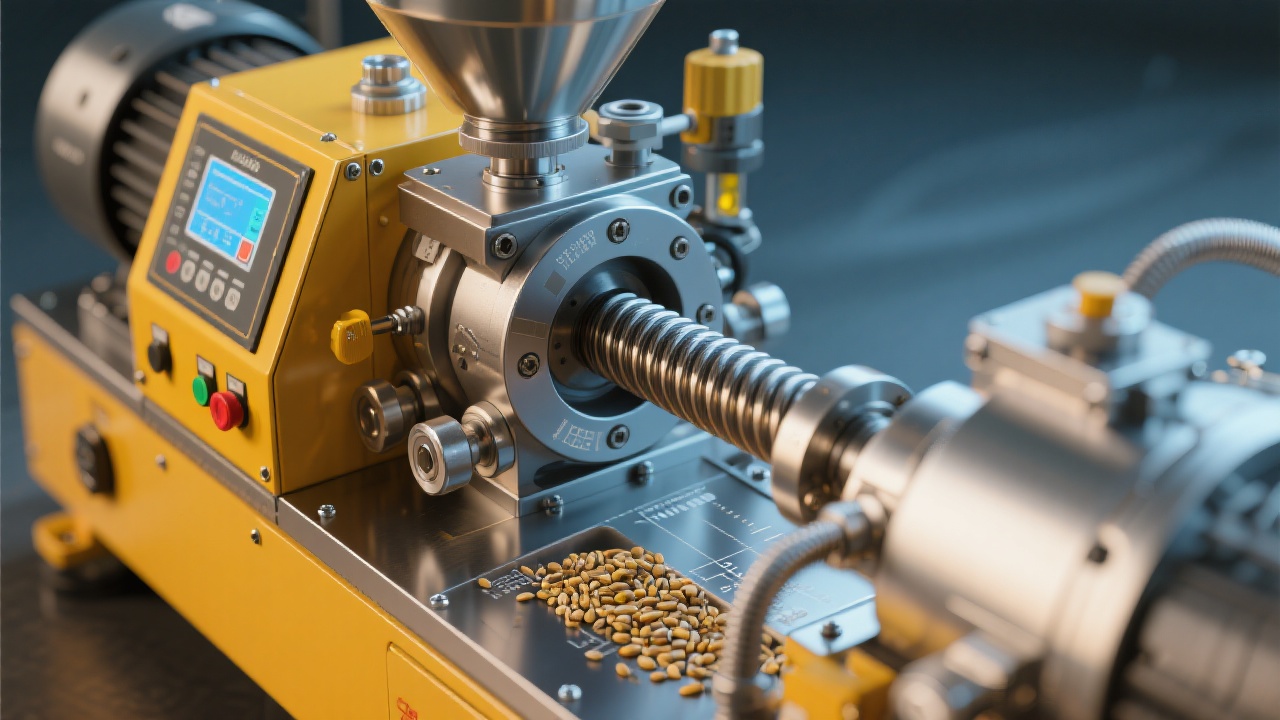

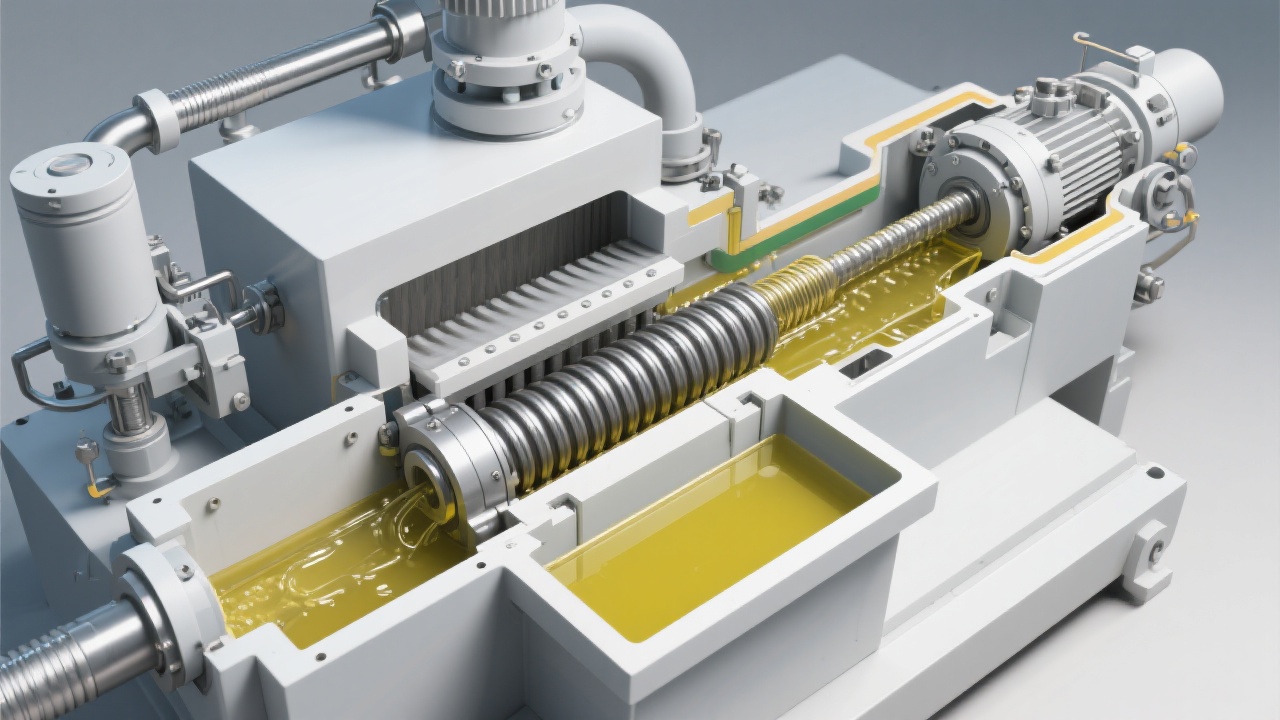

One of the common temperature control modes is segmented heating. We've discovered that this mode has a significant impact on protein denaturation and the retention of flavor substances in the oil. When the temperature is precisely controlled during different segments of the pressing process, it can effectively denature the proteins in the raw materials, which is beneficial for oil extraction. At the same time, it helps to retain the natural flavor substances in the oil, enhancing the overall quality of the product.

For example, in the initial stage of the pressing process, a relatively low temperature is maintained to preserve the flavor substances. As the process progresses, the temperature is gradually increased to promote protein denaturation and improve the oil yield. This mode requires a well - designed temperature control system to ensure the accuracy of temperature adjustment.

Moisture content is another crucial factor that affects the temperature control in the oil pressing process. We've learned that when the moisture content of the raw materials is higher than 8%, the pre - heating temperature needs to be increased. This is because higher moisture content can slow down the heating process and reduce the efficiency of oil extraction.

By increasing the pre - heating temperature, we can effectively reduce the moisture content and improve the fluidity of the raw materials, thereby enhancing the oil yield. On the other hand, when the moisture content is relatively low, a lower pre - heating temperature can be used to avoid over - heating and damage to the raw materials.

During the operation of the temperature control system, various alarm codes may appear. We've summarized some typical alarm codes and their corresponding on - site handling procedures. For example, when the temperature fluctuates by more than ±3℃, it is necessary to check the sealing of the heating coil. This is because a poor - sealed heating coil can cause heat loss and unstable temperature control.

| Alarm Code | Possible Cause | Handling Procedure |

|---|---|---|

| Code 1 | Temperature fluctuation > ±3℃ | Check the sealing of the heating coil |

| Code 2 | Abnormal sensor reading | Calibrate or replace the sensor |

We've found that daily maintenance is essential for the long - term stability of the temperature control system. Regular cleaning of the equipment, inspection of the sensors, and calibration of the temperature control system can effectively prevent potential problems and extend the service life of the equipment.

For example, cleaning the heating elements regularly can prevent the accumulation of dirt and debris, which can affect the heating efficiency. Inspecting the sensors can ensure the accuracy of temperature measurement, and calibrating the temperature control system can maintain the stability of temperature adjustment.

To help you optimize your production efficiency and extend the service life of your equipment, we've prepared a valuable resource. Click to download the Temperature Control Settings Self - Check List PDF.