In the dynamic landscape of the vegetable oil processing industry, the demand for versatile and efficient oil extraction equipment has never been higher. As the market expands to accommodate a diverse range of oilseeds such as peanuts, soybeans, and rapeseeds, processors are constantly on the lookout for solutions that can meet the challenges of multi - variety oil production. Enter the medium - sized multi - functional screw oil press, a game - changer in the realm of vegetable oil extraction.

Currently, vegetable oil processing plants face several pain points when it comes to multi - category oil production. Traditional oil presses often lack the flexibility to handle different types of oilseeds efficiently. For instance, a press designed for peanuts may not perform optimally when used for soybeans, leading to lower oil yields and higher production costs. Moreover, these traditional machines are usually energy - intensive, consuming large amounts of electricity and increasing operational expenses. Additionally, they may require a significant amount of manual labor for operation and maintenance, which further adds to the cost and inefficiency.

Medium - sized screw oil presses are engineered to address these pain points. They have excellent adaptability to various raw materials. Take peanuts, soybeans, and rapeseeds as examples. These presses can adjust their operating parameters according to the characteristics of different oilseeds. For peanuts, which have a relatively high oil content, the press can apply appropriate pressure to extract oil efficiently. In the case of soybeans, which have a lower oil content but a higher protein content, the press can use a different squeezing process to ensure maximum oil extraction. On average, compared with traditional single - function oil presses, medium - sized screw oil presses can increase the oil yield by about 5 - 8%. This means that for every ton of oilseeds processed, an additional 50 - 80 kilograms of oil can be obtained, significantly improving the economic benefits of the plant.

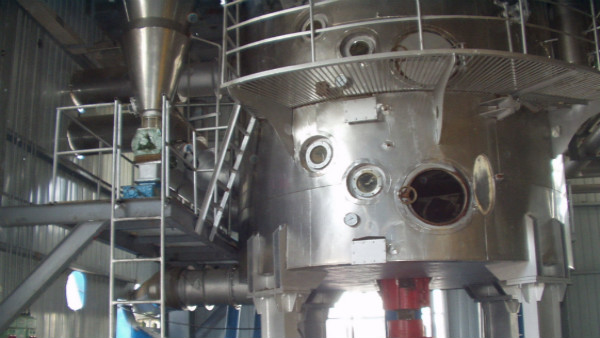

One of the notable features of medium - sized screw oil presses is their compact structure and easy operation. Their compact design allows them to be installed in limited spaces, which is particularly beneficial for small and medium - sized oil processing plants or factories with space constraints. Unlike large - scale oil presses that require a large area for installation and complex infrastructure, these medium - sized presses can be quickly deployed and integrated into existing production lines. In terms of operation, they are designed with user - friendly interfaces, which means that even operators with limited technical skills can quickly master the operation methods. This significantly reduces the need for highly skilled labor, saving labor costs. In fact, it is estimated that using a medium - sized screw oil press can reduce labor requirements by up to 30% compared to traditional oil presses.

The screw shaft design and temperature control system are two crucial factors that affect the quality of the oil and production efficiency. The screw shaft is the core component of the oil press, and its design determines the squeezing force and the flow of oilseeds. A well - designed screw shaft can ensure uniform pressure distribution during the squeezing process, which not only improves the oil yield but also protects the quality of the oil. The temperature control system, on the other hand, can maintain the optimal temperature during the oil extraction process. Different oilseeds require different temperature ranges for oil extraction. For example, rapeseeds need a relatively higher temperature to break down the cell walls and release the oil, while soybeans are more sensitive to temperature and require a more moderate temperature to avoid protein denaturation. By precisely controlling the temperature, the medium - sized screw oil press can ensure that the oil quality is stable and the production efficiency is maximized. It can also reduce energy consumption by about 15 - 20% compared to presses without advanced temperature control systems.

In the international market, there is a growing demand for high - quality, energy - efficient, and versatile oil extraction equipment. Medium - sized screw oil presses meet these market demands perfectly. They are suitable for both small - scale independent oil processing operations and large - scale factory expansions. Their multi - functionality allows them to adapt to different market needs in various countries and regions. For B2B exporters, these presses can be a valuable product in their portfolio. They can help exporters enter new markets and increase their market share. Moreover, as more and more countries are focusing on sustainable development and energy conservation, the energy - saving features of these presses make them even more attractive in the international market.

Overall, medium - sized multi - functional screw oil presses are a revolutionary solution for the vegetable oil processing industry. They can help your factory achieve higher yields, lower energy consumption, and stronger market adaptability. If you want to learn more about how these presses can be customized to meet your specific production needs, click here to contact us.