When it comes to selecting a spiral oil press for your medium or small-scale oil mill, overlooking critical technical parameters can cause significant inefficiencies — soaring energy costs, limited oil yield, and compromised oil quality. In a competitive landscape, understanding the interplay of machine design, raw material traits, and operational controls is vital to unlock both cost-effectiveness and quality enhancement.

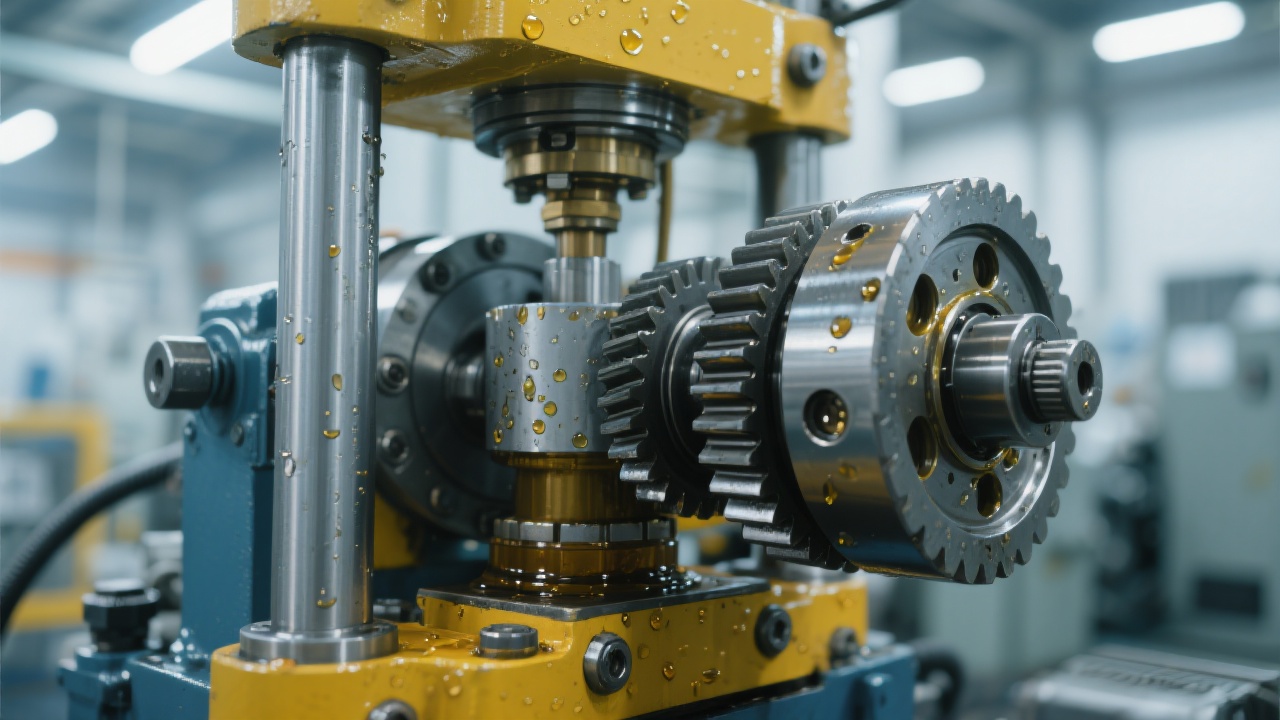

The structure of the spiral shaft—its pitch, flight thickness, and compression zones—directly affects how material is conveyed and pressed. A well-optimized shaft boosts throughput and maximizes oil yield.

Studies indicate upgrading to a precision-engineered spiral screw can improve oil yield by up to 12% while cutting down energy use by 10%.

Maintaining optimal pressing temperature is crucial. Too low a temperature impedes oil flow and reduces extraction efficiency; too high causes degradation in oil taste and nutritional value.

| Oilseed Type | Optimal Pressing Temp (°C) | Energy Consumption (kWh/ton) |

|---|---|---|

| Peanut | 85-105 | 110-130 |

| Soybean | 75-90 | 120-140 |

| Rapeseed | 60-80 | 100-120 |

Careful regulation of temperature not only preserves critical oil qualities but also reduces unnecessary energy waste.

Each oilseed presents unique compression and moisture characteristics affecting extraction:

Ignoring these intrinsic differences often leads to mechanical strain or suboptimal output.

Preheating seeds before pressing significantly reduces pressing resistance, improving oil flow and yield. Practical implementation of integrated preheating can:

According to industry veterans, the initial investment in preheating pays off within months due to energy savings coupled with improved productivity.

“Many small to medium oil mills mistakenly prioritize machine power over compatibility with their raw materials and process controls, resulting in wasted energy and poor product quality.” – Dr. Wei Zhang, Oil Processing Consultant

Investing in oversized motors or ignoring machine-material synergy leads to 'pseudo-efficiency'—higher input without proportional output gains. Therefore, focus on balanced specs that align with your production scale and seed characteristics.

Optimizing energy consumption in spiral pressing is not just about hardware but also operational discipline:

Case study evidence shows that implementing these measures alongside proper machine selection has led to average energy reduction of 18% without sacrificing output.

A mid-sized oil mill specializing in soybean oil revamped its spiral press selection by integrating customized screw design and preheating. Within six months, the mill achieved:

This is a testament to how strategic equipment investment, matched to feedstock and process control, drives substantial business value.

When selecting your spiral oil press, focus beyond headline specs:

Adopt this holistic perspective to reduce operational costs while guaranteeing premium oil quality.