Pressing temperature is a critical factor influencing the quality of oil. Physicochemical indicators such as acid value and peroxide value are directly affected by the temperature during the pressing process. For instance, when the pressing temperature is too high, the acid value of the oil tends to increase, which indicates a higher degree of oil oxidation and hydrolysis. A study shows that for every 10°C increase in temperature above the optimal range, the acid value of the oil can rise by approximately 0.1 - 0.2 mg KOH/g. Similarly, the peroxide value, which reflects the degree of oil oxidation, also shows a significant upward trend with increasing temperature. The ideal range of peroxide value for high - quality edible oil is generally below 10 meq/kg, and improper temperature control can easily push it beyond this standard.

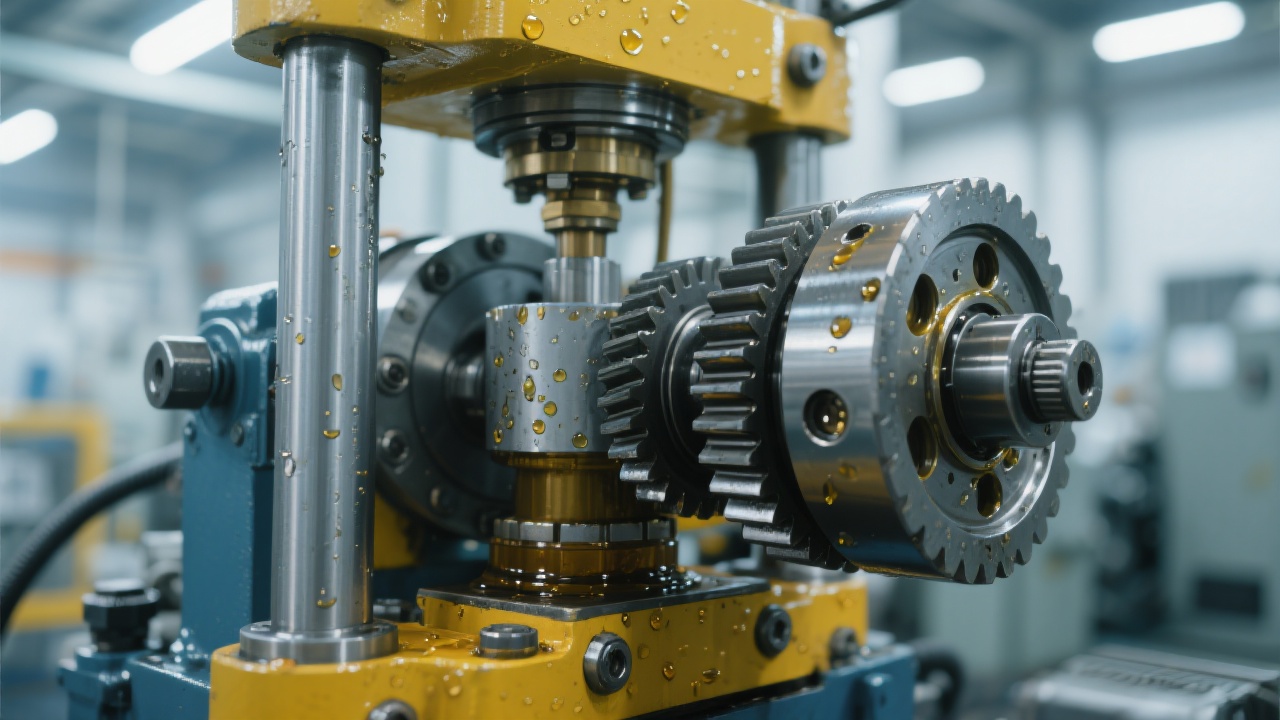

Small and medium - sized screw oil presses are equipped with advanced temperature control systems. These systems offer several technical advantages. Firstly, they can achieve precise temperature control within a small error range, usually ± 2°C. This high - precision control ensures that the oil pressing process is carried out under the most suitable temperature conditions. Secondly, modern temperature control systems are highly automated. They can adjust the temperature in real - time according to the set parameters, reducing the need for manual intervention and improving production efficiency.

The realization of these temperature control systems mainly relies on sensors and heating elements. Sensors continuously monitor the temperature inside the press chamber and transmit the data to the control unit. The control unit then adjusts the power of the heating elements to maintain the temperature within the set range. For example, in some advanced models, infrared sensors are used to measure the temperature more accurately, and electromagnetic heating elements are employed for rapid and uniform heating.

Different oil raw materials, such as peanuts, soybeans, and rapeseeds, have different suitable pressing temperature ranges. Here is a comparison table:

| Oil Raw Material | Suitable Pressing Temperature Range (°C) |

|---|---|

| Peanuts | 110 - 120 |

| Soybeans | 90 - 100 |

| Rapeseeds | 100 - 110 |

The pre - heating function in screw oil presses plays a crucial role in improving material fluidity and oil extraction efficiency. When the raw materials are pre - heated, the viscosity of the oil in the materials decreases, making it easier for the oil to flow out during the pressing process. For example, pre - heating peanuts to the appropriate temperature can increase the oil extraction efficiency by about 3 - 5% compared to non - pre - heated peanuts. Moreover, pre - heating also helps to break down the cell structure of the raw materials, further promoting the release of oil.

There are two common misoperation cases related to temperature control. One is setting the temperature too high, which can cause the raw materials to burn and produce a burnt smell. This not only affects the flavor of the oil but also reduces the nutritional value of the oil. The other is setting the temperature too low, which leads to poor material fluidity and low oil extraction efficiency. In some cases, the oil may not be able to be completely extracted, resulting in a waste of raw materials.

To achieve energy - saving and efficiency improvement, small and medium - sized oil mills should match the equipment parameters based on the characteristics of the raw materials. For example, for raw materials with high oil content like peanuts, a higher pre - heating temperature and a relatively slower pressing speed can be set to ensure full oil extraction. For soybeans with lower oil content, a moderate pre - heating temperature and a faster pressing speed can be adopted to improve production efficiency.

In conclusion, understanding the relationship between pressing temperature and oil quality, as well as the technical features of small and medium - sized screw oil presses, is essential for small and medium - sized oil mills. Learn about our small and medium - sized screw oil press solutions and make every drop of oil purer.