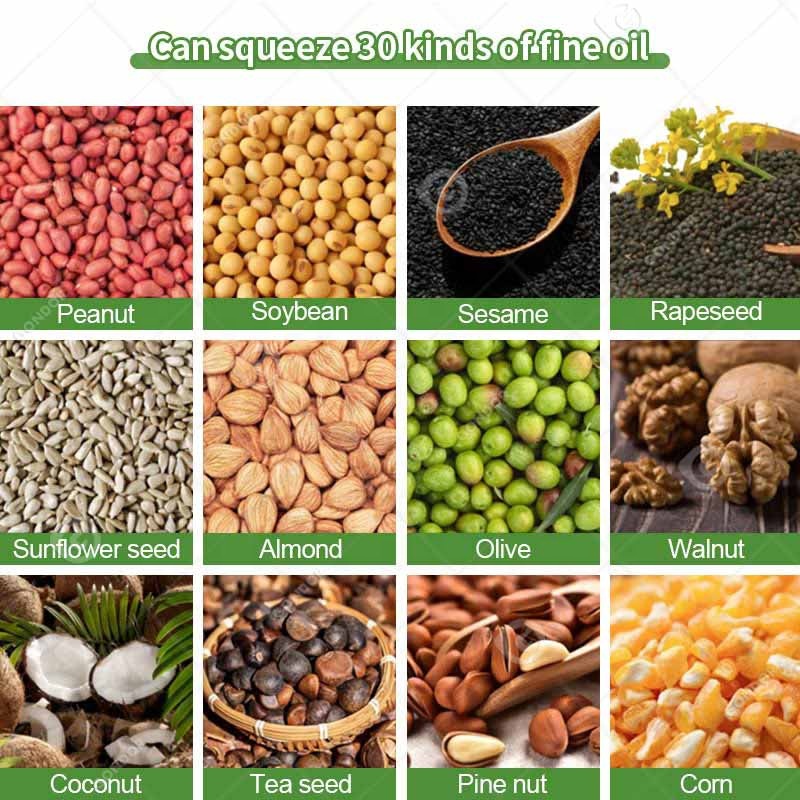

In the global plant oil processing industry, choosing the right equipment isn't just about capacity—it's about adaptability, efficiency, and long-term ROI. Many international buyers face a common challenge: balancing high output with low energy consumption while ensuring consistent oil quality across diverse raw materials like soybeans, peanuts, sunflower seeds, and sesame.

The medium-scale screw oil press is engineered to handle a wide range of oilseeds—from 75% moisture content in fresh peanuts to 10% in dried canola. Unlike single-purpose presses, this machine maintains >92% extraction efficiency regardless of feedstock type. For example, a Nigerian agro-processing firm reported a 14% increase in yield after switching from batch hydraulic presses to our spiral design—especially noticeable in high-fiber crops like sesame.

| Oilseed Type | Avg. Yield (%) | Energy Use (kWh/kg) |

|---|---|---|

| Soybean | 93.2% | 0.18 |

| Peanut | 91.5% | 0.21 |

| Sunflower | 90.7% | 0.19 |

Our presses use AISI 304 stainless steel for the screw shaft and hardened alloy steel components—proven to reduce wear by up to 40% compared to standard carbon steel models. In a 2-year field test with a Chilean olive oil producer, no major part replacements were needed despite continuous operation under humid conditions. This durability directly translates into lower maintenance costs—a key factor for overseas buyers evaluating total cost of ownership.

The modular structure reduces floor space by 30% versus older horizontal presses—an advantage for small-to-mid-sized processors in urban areas or limited industrial zones. One Indonesian customer saved $4,200/year on labor alone by shifting from manual feeding to semi-automatic control. With intuitive touchscreen interface and minimal training required, even non-engineers can operate it efficiently.

Unlike traditional systems that risk overheating and degrading oils, our patented thermal regulation system keeps internal temps between 65–75°C during pressing—ideal for preserving natural antioxidants. A Moroccan client saw a 25% improvement in shelf life for their cold-pressed argan oil, which helped them meet EU food safety standards for export markets.

According to FAO data, global edible oil production grew at 3.2% CAGR from 2020–2024—with emerging markets in Africa, Southeast Asia, and Latin America leading demand. The medium screw press is now the preferred choice for new plants due to its flexibility, scalability, and compliance with ISO 22000 standards. Whether you're building a facility in Kenya or expanding in Brazil, this equipment delivers both performance and peace of mind.

“ In my 18 years in B2B exports, I’ve never seen a machine so well-balanced between technical excellence and real-world usability.” — Carlos Mendez, Procurement Director, AgriTech Solutions (Colombia)

Whether you’re a domestic processor looking to scale or an international buyer seeking reliable, efficient solutions—you need a machine that performs consistently across climates, seasons, and crop types. The medium screw oil press isn’t just another piece of machinery—it’s your competitive edge in a crowded global market.

Ready to Boost Your Output? Explore Export-Ready Models Today →