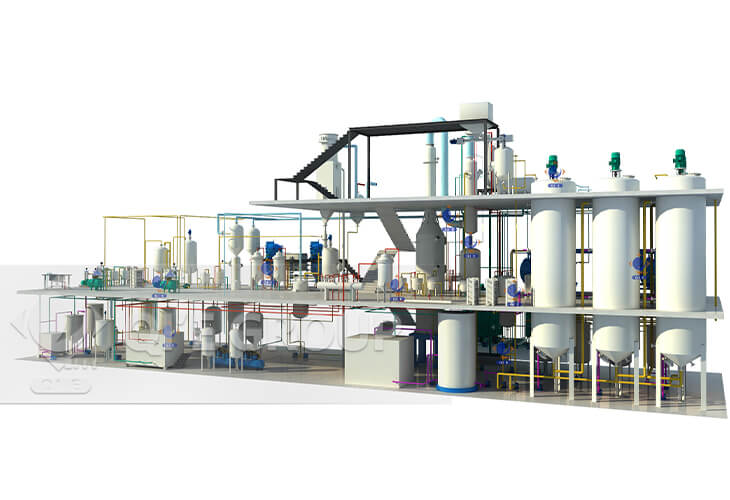

In the global B2B market of vegetable oil processing, large hydraulic/pre - presses have emerged as the key equipment for technology upgrading. Specifically designed to meet the industrial demands of large - scale oil processing operations, these machines offer a one - stop solution for all types of oil pressing needs.

One of the significant features of large hydraulic/pre - presses is their ability to cover a wide range of pressing requirements, from hot pressing to cold pressing. Different pressing methods are suitable for various types of oilseeds, ensuring that the best quality oil can be extracted. For example, hot pressing can increase the oil yield, while cold pressing can preserve more nutrients in the oil. This flexibility allows vegetable oil processing enterprises to diversify their product lines and meet different market demands.

These presses are equipped with advanced technologies and have a sturdy design. They can withstand a large number of stamping operations, ensuring stable and long - term operation. In fact, according to our data, a well - maintained large hydraulic/pre - press can operate continuously for up to 800 hours per month with a very low failure rate of less than 2%. This high - reliability performance is crucial for large - scale oil processing enterprises, as it reduces production downtime and increases overall efficiency.

The operation and maintenance of large hydraulic/pre - presses are quite convenient. The user - friendly control panel allows operators to easily adjust the pressing parameters according to different oilseeds and pressing requirements. Moreover, the modular design of the machine makes it easy to disassemble and assemble for maintenance. A skilled technician can complete a routine maintenance check in less than 2 hours, which significantly optimizes the production process and reduces labor costs.

Energy conservation and environmental protection are also important features of these presses. The advanced hydraulic system is designed to minimize energy consumption. Compared with traditional presses, they can save up to 30% of energy. At the same time, this design also helps to ensure the quality of the extracted oil, as it reduces the heat generated during the pressing process, which may otherwise damage the nutrients in the oil.

Large hydraulic/pre - presses can process a variety of vegetable oils, including soybean oil, peanut oil, rapeseed oil, sunflower oil, and more. This versatility enables vegetable oil processing enterprises to expand their product portfolios and capture a larger market share.

Many vegetable oil processing enterprises have already benefited from using large hydraulic/pre - presses. For example, a well - known oil processing company in South America increased its production efficiency by 40% after installing our large hydraulic/pre - presses. They also improved the quality of their oil products, which led to a 30% increase in sales revenue within one year.

In conclusion, large hydraulic/pre - presses are the ideal choice for vegetable oil processing enterprises to improve production efficiency, ensure product quality, and achieve maximum economic benefits. They are the key to seizing business growth and market opportunities. If you are looking to upgrade your vegetable oil processing technology, don't miss out on this great opportunity!

Contact us today to learn more about our large hydraulic/pre - presses and how they can transform your business!