In today’s global market, demand for high-purity, naturally extracted oils—whether for food, cosmetics, or industrial use—is growing at a rate of 7.2% annually (Source: Grand View Research, 2024). For manufacturers aiming to meet this trend while cutting costs and boosting output, the right equipment is no longer optional—it’s essential.

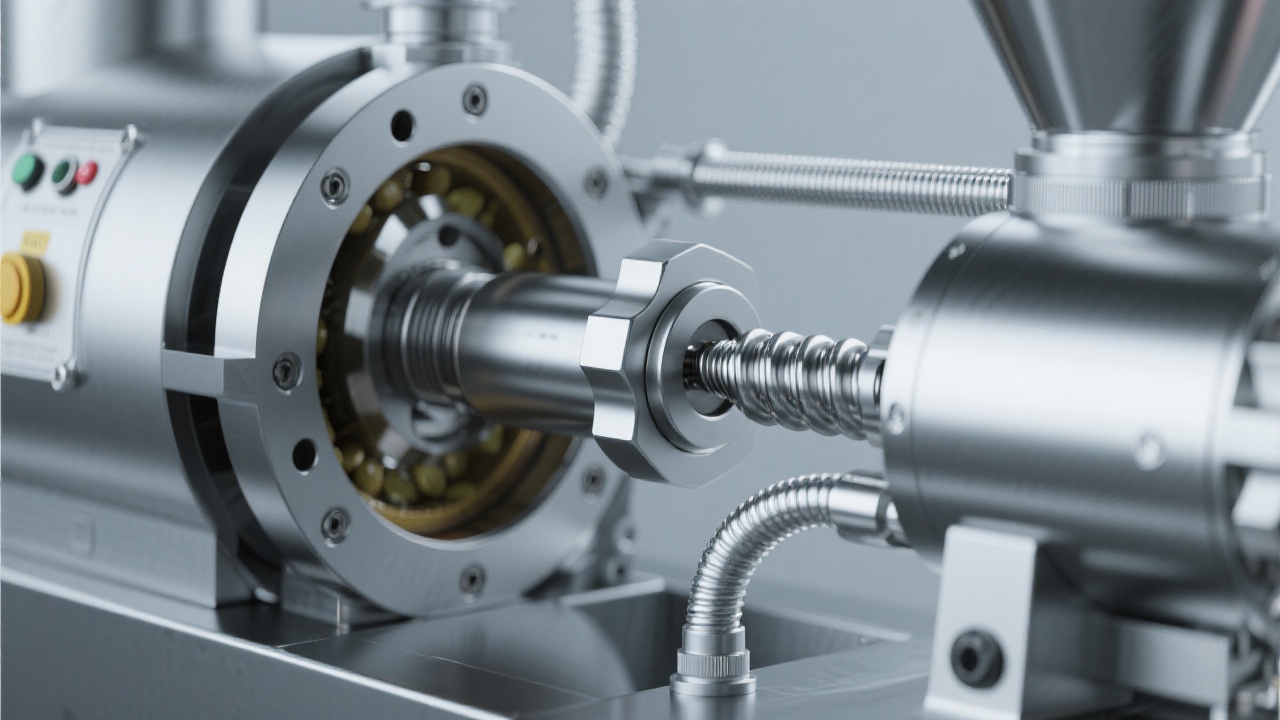

Traditional oil presses often sacrifice quality for speed—or vice versa. But with the Penguin Group Multi-Function Screw Press, users gain both: consistent extraction efficiency up to 92% (vs. industry average of 78%) and minimal nutrient loss during cold pressing.

| Feature | Penguin Press | Standard Equipment |

|---|---|---|

| Oil Yield (%) | 92% | ~78% |

| Waste Residue (%) | ≤5% | ≥12% |

| Continuous Run Time | 24/7 for 14 days | Max 8 hrs/day |

The secret lies in its dual-mode temperature control system. In cold press mode (≤40°C), it retains delicate compounds like omega-3s and antioxidants—ideal for premium cosmetic oils. In hot press mode (60–85°C), it increases yield without degrading quality, making it perfect for industrial applications such as bio-lubricants or biodiesel feedstock.

A case study from an Indian agro-processing firm shows how switching to the Penguin press reduced their waste by 68% over six months—a direct cost savings of $18,000/year on raw material alone.

Unlike bulky legacy machines, the compact design allows easy integration into existing production lines—even small-scale facilities benefit from its modular setup. Operators report a 40% faster learning curve thanks to the intuitive touchscreen interface and automated diagnostics.

One Middle Eastern client used it to launch a new line of organic coconut oil for skincare brands—now selling in Europe and North America—with a 30% higher margin than before.

Whether you're producing edible oils, natural beauty products, or industrial-grade lubricants, this isn’t just another piece of machinery—it’s your competitive edge.

Ready to transform your oil extraction process? Let’s talk about how the Penguin Group Screw Press can help you scale efficiently, reduce waste, and stand out in crowded markets.

Get Your Free Performance Report + Case Study