In today’s dynamic vegetable oil industry, the ability to process multiple oilseed varieties efficiently and reliably has become a decisive factor for manufacturers worldwide. Markets demand increasing flexibility—not only in raw materials like soybeans, peanuts, sesame, and sunflower seeds but also in production scales and output consistency. Traditional hydraulic presses and fixed-parameter equipment often fall short when tasked with adapting quickly to such diverse inputs, resulting in lower yields, extended downtime, and increased operational costs.

Conventional oil pressing machines are typically designed with rigid settings optimized for one type of oilseed. This inflexibility poses challenges when switching between different oil materials due to variations in oil content, seed hardness, moisture, and texture. Operators often grapple with manual adjustments that don’t yield optimal pressure or temperature, causing subpar pressing efficiency. Moreover, mechanical wear increases, and energy consumption rises where the machine cannot adjust dynamically, impacting both throughput and maintenance costs.

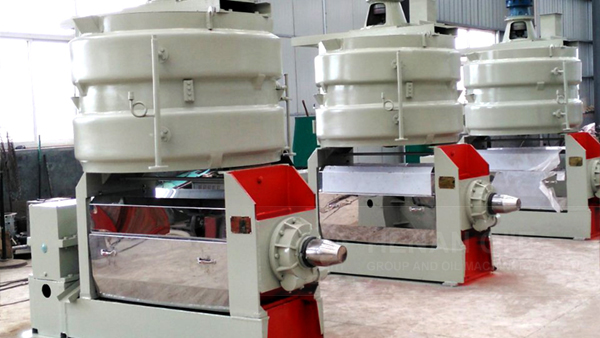

The 6YL-185 spiral hydraulic oil press was engineered specifically with versatility at its core. Its advanced hydraulic control system enables operators to precisely adjust pressing parameters such as pressure, temperature, and screw speed in real time according to the unique requirements of each oilseed type. This capability ensures maximized oil extraction rate—commonly reaching over 95% efficiency—while maintaining quality and nutritional value.

For example, when processing peanuts with higher oil content, the 6YL-185 can reduce screw speed and increase pressure gently, avoiding excessive heat buildup that might degrade oil quality. Conversely, when extracting oil from harder seeds like sesame, the machine’s robust hydraulic unit allows for incremental pressure increases without compromising mechanical integrity or causing undue wear. The result is consistently optimized yields regardless of the seed variety.

Field data collected from multiple production sites globally validate the 6YL-185’s adaptability:

| Oilseed | Average Oil Extraction Rate | Throughput (tons/day) |

|---|---|---|

| Soybean | 94.7% | 5.8 |

| Peanut | 95.3% | 6.2 |

| Sesame | 93.9% | 4.5 |

These figures stem from precise control of hydraulic pressure (up to 185 MPa) and temperature adjustments maintained between 90° to 130°C, ensuring optimal oil flow and pressing pressure for each variety.

Backed by years of B2B export experience, our company ensures that every 6YL-185 unit meets rigorous international standards. Clients benefit not only from a high-performance machine but also from comprehensive, professional after-sale service including remote diagnostics, timely spare parts supply, and on-site technical assistance worldwide. This ensures maximum uptime and reliability across diverse markets.

Unlike many competitors, our tailored approach to hydraulic press customization combined with expert application consultation has earned client trust across Asia, Africa, and Latin America—regions with the highest demand for adaptable oil extraction solutions.

When benchmarked against comparable spiral hydraulic presses on the market, the 6YL-185 stands out through:

These factors collectively contribute to lowered total cost of ownership, faster return on investment, and a competitive edge for producers seeking wide raw material adaptability.

"Choosing the right oil press equipment is pivotal for sustainable growth in the vegetable oil industry. The 6YL-185’s proven flexibility and reliability set a new standard for multi-seed processing—enabling producers to innovate with confidence and operational efficiency."

For global purchasers striving to optimize their oil extraction capacity across various seeds without sacrificing quality or increasing costs, the 6YL-185 spiral hydraulic oil press machine offers an unmatched solution. Discover how this versatile technology can transform your production line and position your business for lasting success in the competitive world market.