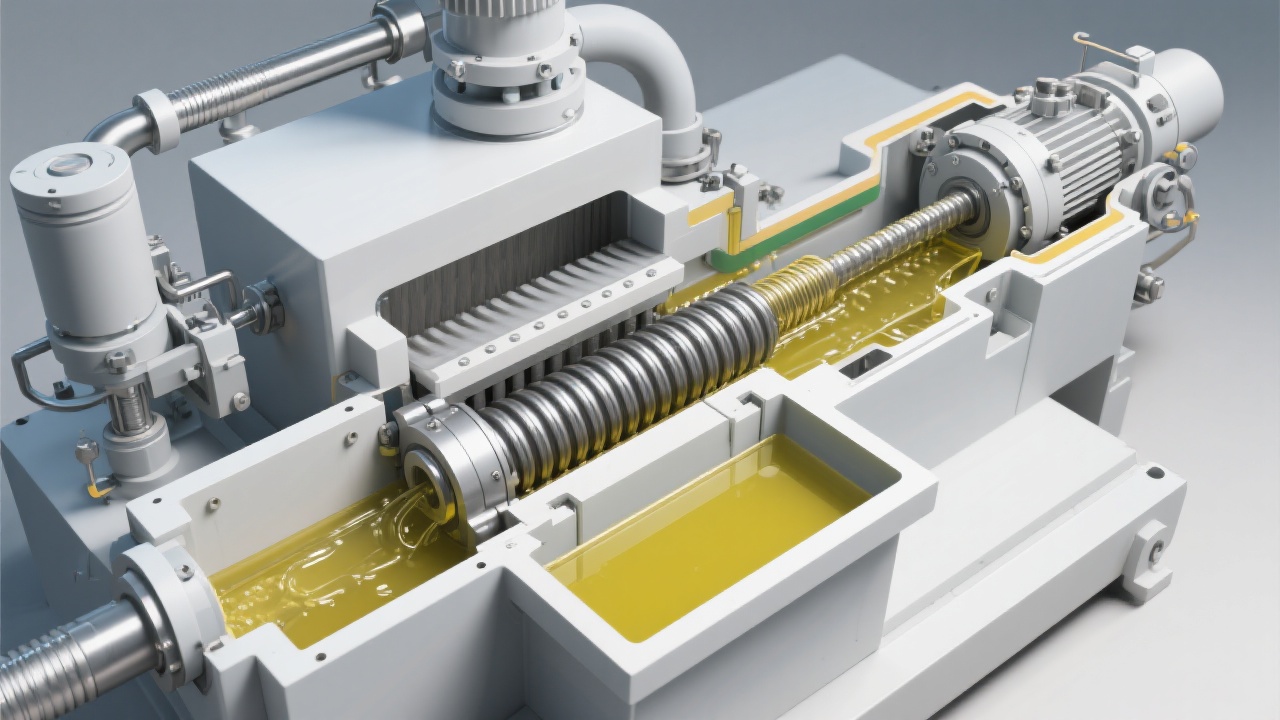

The medium - sized screw oil press stands out with its remarkable core technical advantages in energy - saving and high output. The high - efficiency screw shaft design is a key feature. Through precise engineering, the screw shaft can exert a more uniform and powerful pressure on the oil - bearing materials. Compared with traditional oil presses, this design can increase the oil output rate by about 10%. For example, in a large - scale vegetable oil processing plant, when using the traditional press, the oil output from a ton of peanuts might be around 400 kg, while with the new medium - sized screw oil press, it can reach up to 440 kg.

The accurate temperature control system is another highlight. Maintaining the optimal temperature during the pressing process is crucial for both energy - saving and oil quality. This system can reduce energy consumption by approximately 15%. In a comparison chart of traditional vs. new oil press energy efficiency (as shown in IMAGE - URL1), it can be clearly seen that the new press consumes significantly less power while achieving better results.

One of the significant advantages of the medium - sized screw oil press is its versatility. It can handle a variety of raw materials such as peanuts, soybeans, and rapeseeds. This multifunctionality brings great value to production flexibility. A processing enterprise no longer needs to purchase different types of oil presses for different raw materials. According to market research, enterprises using this multi - purpose oil press can increase their production flexibility by about 30%. They can quickly switch between different raw materials according to market demand, which is especially important in a volatile market environment.

The medium - sized screw oil press features a compact structure and simple operation. Its compact design saves a lot of space in the production workshop. In a typical vegetable oil processing plant, it can save about 20% of the floor space compared to traditional oil presses. Moreover, the simple operation reduces the need for highly skilled workers, thus optimizing manpower costs. With proper training, an ordinary worker can operate this oil press proficiently, which is expected to reduce labor costs by about 12%.

The temperature control system and screw propulsion design play a vital role in ensuring oil quality and stable production. The precise temperature control system can prevent the oil from being over - heated or under - heated, which helps to maintain the natural flavor and nutritional value of the oil. The screw propulsion design ensures a continuous and stable pressing process, reducing the probability of production interruptions. Statistics show that the rate of production interruption can be reduced by about 25% compared to traditional presses, which is of great significance for large - scale production enterprises.

In the context of the global market, the demand for energy - saving and high - efficiency oil presses is increasing. The medium - sized screw oil press, with its outstanding performance in energy - saving, high output, and multi - functionality, has strong competitiveness in the B2B export market. According to industry reports, the global market for vegetable oil processing equipment is growing at an annual rate of about 8%. This oil press, which can meet the needs of different customers in different regions, is expected to capture a larger market share. It provides an ideal solution for vegetable oil processing enterprises around the world, allowing them to reduce energy consumption costs and improve oil output efficiency, and truly making every investment translate into higher returns.

If you are looking for a reliable and efficient oil - pressing solution for your vegetable oil processing enterprise, the medium - sized screw oil press is definitely worth considering. Click here to learn more about this amazing product and take the first step towards a more profitable and sustainable production process.