We've noticed that in the operation of medium-sized screw oil presses, many oil mills often encounter common pain points such as low oil yield, turbid oil products, and frequent equipment alarms. These issues not only affect production efficiency but also have a negative impact on the quality of the final products. In fact, the root cause behind these phenomena is often related to the temperature control system of the oil press.

The temperature control system is the core guarantee for the efficient and stable operation of medium-sized screw oil presses. Let's first delve into the real reasons behind these common pain points. Low oil yield can be attributed to improper temperature control during the pressing process. If the temperature is too low, the oil will not be fully released from the raw materials, resulting in a decrease in oil yield. On the other hand, if the temperature is too high, the oil may be oxidized, leading to a loss of flavor and a decrease in quality. Turbid oil products are often caused by the incomplete separation of oil and impurities due to improper temperature, which affects the emulsification stability of the oil. Equipment frequent alarms are usually a sign of abnormal temperature control, such as temperature fluctuations or sensor malfunctions.

Now, let's take a deep dive into the temperature control principle. Temperature has a significant impact on protein denaturation, oil oxidation, and emulsification stability during the pressing process. From a physical and chemical perspective, when the temperature rises, proteins in the raw materials will denature, which helps to release the oil. However, if the temperature is too high, the oil will be oxidized, affecting its quality. Moreover, temperature also affects the emulsification stability of the oil. By understanding these physical and chemical mechanisms, we can better appreciate the importance of temperature control in the oil pressing process.

Next, we'll provide a scenario-based operation guide. Different raw materials have different moisture contents, and we need to adjust the preheating temperature range accordingly. For example, for raw materials with high moisture content, we need to set a higher preheating temperature to ensure that the moisture is removed and the oil is released more easily. In addition, the position of the sensors also plays a crucial role in temperature control accuracy. By reasonably setting the sensor position, we can more accurately monitor the temperature in the pressing chamber and adjust the heating system in a timely manner.

When it comes to abnormal situations, we've got you covered. We'll interpret typical alarm codes, such as when the temperature fluctuates by more than ±3°C. We'll also provide a quick troubleshooting flowchart and a maintenance list. For instance, if the temperature is too high, we can first check if the heating system is overheating, then examine the sensors to see if they are working properly. By following these steps, we can quickly identify and solve problems.

Finally, let's talk about some hidden tips for extending the equipment life. Regularly cleaning the heating coils can prevent the accumulation of dirt and ensure uniform heating. Calibrating the temperature sensors can improve the accuracy of temperature measurement. Keeping a temperature control log can help us track the equipment's operation status over time and detect potential problems in advance. These seemingly small details can have a big impact on the long - term operation of the oil press.

To give you a more intuitive understanding, let's look at some data comparisons. A temperature fluctuation of ±1°C has a much smaller impact on the clarity of the oil compared to a fluctuation of ±5°C. With a smaller temperature fluctuation, the oil is clearer, and the quality is more stable. This shows the importance of precise temperature control.

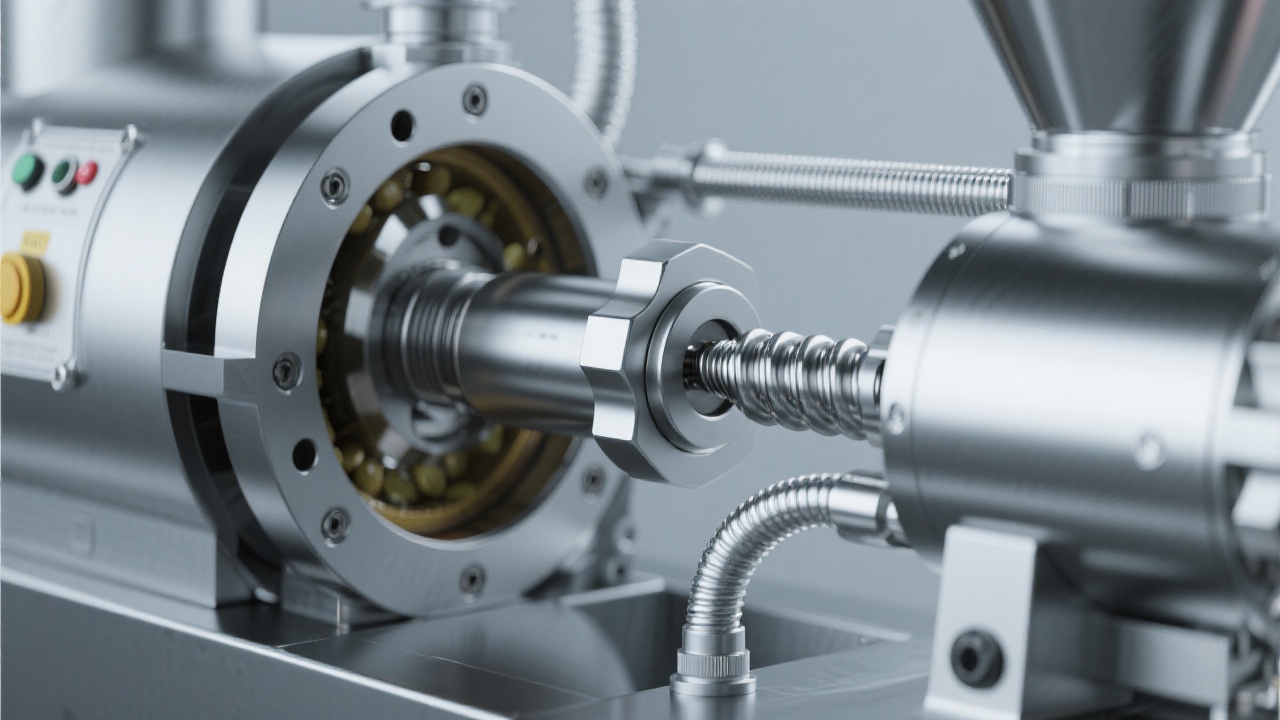

We also recommend using an information chart, such as a sensor layout diagram, to help you better understand how to optimize the temperature control system. This diagram can clearly show the best positions for sensors to achieve the highest temperature control accuracy.

Are you ready to optimize your oil press's temperature control system? Click here to get the PDF of the Temperature Control Settings Self - Check List, which provides you with a practical and reusable tool to ensure the efficient and stable operation of your oil press.