In an era driven by sustainable innovation and efficiency, the oil extraction industry is witnessing transformative advancements. Central to these developments are hydraulic oil presses equipped with cutting-edge hydraulic system designs aimed at maximizing oil recovery rates. As demand surges for environmentally friendly and cost-effective solutions, modern hydraulic presses emerge as indispensable equipment that seamlessly balance high performance with eco-conscious operations.

Hydraulic oil presses today boast versatile applicability, efficiently processing an extensive range of seeds and nuts—including sunflower, rapeseed, soybean, sesame, walnuts, and more. Their hydraulic systems ensure consistent, stable work pressure crucial for high extraction efficiency, adapting to varying seed hardness and oil content. This adaptability means enterprises can optimize throughput without frequent adjustments or interruptions.

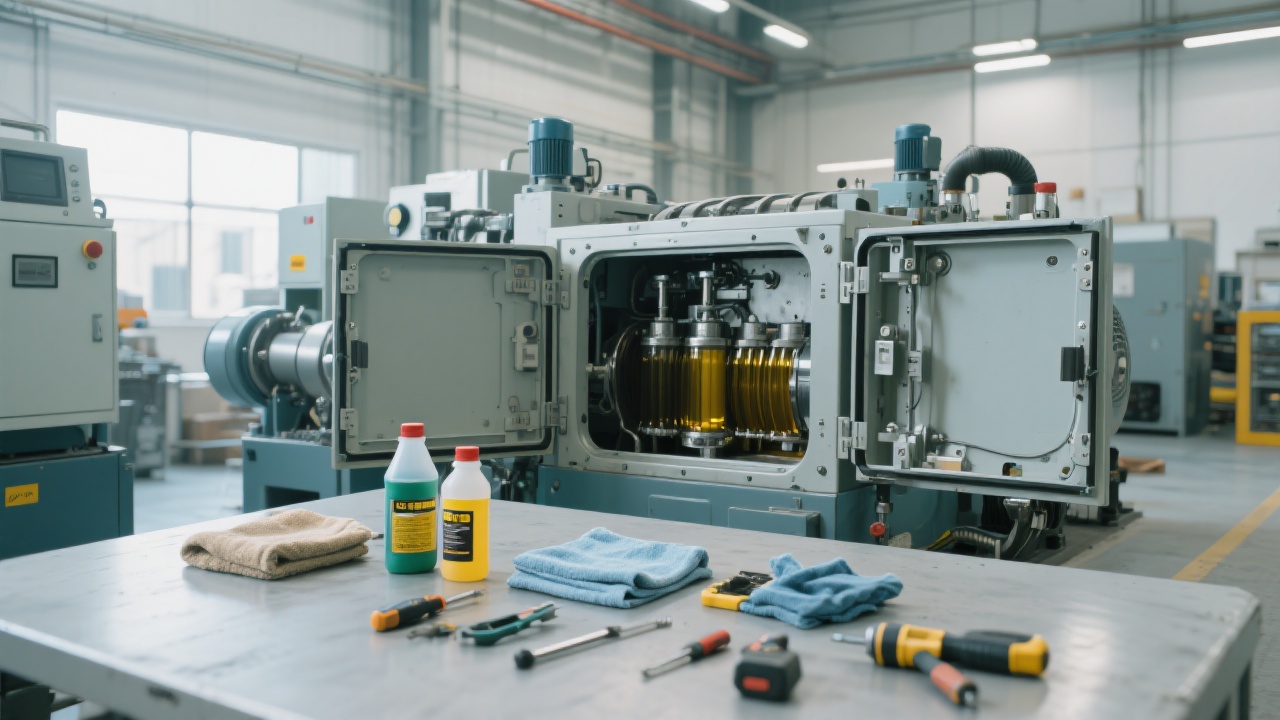

Furthermore, these presses incorporate fully automated control systems that simplify operation, enabling less reliance on specialized technical staff. By integrating sensors and programmable logic controllers (PLCs), operators enjoy precise pressure regulation and process monitoring, which reduce operator fatigue and human error.

| Seed Type | Average Oil Recovery Rate (%) | Traditional Mechanical Press Efficiency (%) |

|---|---|---|

| Sunflower Seeds | 48 – 52 | 40 – 45 |

| Rapeseed | 42 – 46 | 35 – 40 |

| Sesame | 55 – 60 | 50 – 55 |

As shown above, the optimized hydraulic design results in oil recovery improvements of approximately 10-15% compared to mechanical presses, crucial for boosting profitability in highly competitive markets.

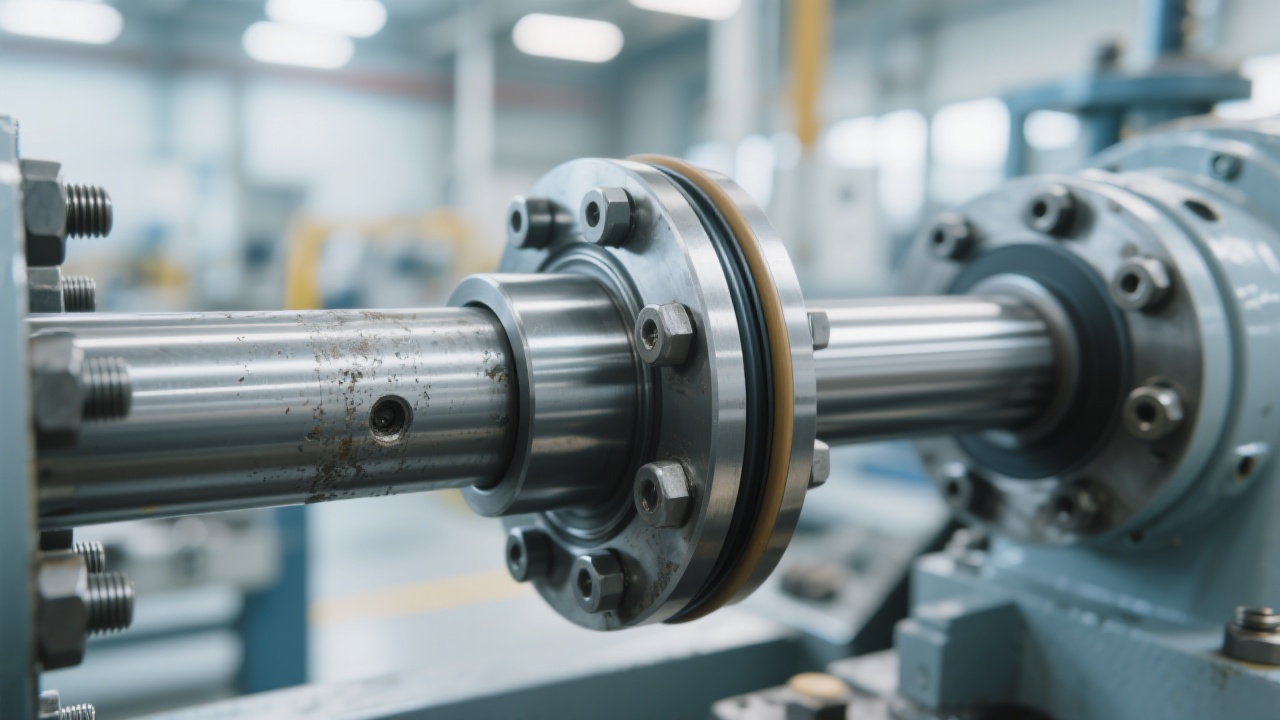

The core advantage of modern hydraulic presses lies in the precision of pressure control. Utilizing proportional valves and robust hydraulic pumps, these systems dynamically adjust operative pressure within a tight margin of ±2%. This stability directly enhances oil yield by preventing pressure fluctuations that could lead to incomplete extraction or seed damage.

Moreover, the integration of pressure sensors and feedback loops enables real-time adjustments, maintaining optimal compression profiles tailored to specific raw material batches. These advancements not only elevate oil recovery but also extend equipment longevity by minimizing mechanical stress.

Beyond performance, environmental sustainability stands as a critical benchmark in hydraulic press design. Energy-efficient hydraulic pumps combined with optimized cycle times reduce electricity consumption by up to 20% compared to older models. Additionally, the presses produce significantly less waste cake residue by maximizing seed pressing efficiency, promoting resource conservation.

Many of these systems comply with international eco-certifications such as ISO 14001 and RoHS directives, assisting businesses in enhancing their green credentials. Companies adopting such technology benefit not only through operational savings but also by aligning their brand with global sustainability trends.

Medium-sized enterprises seeking scalable solutions will find these hydraulic presses particularly advantageous, as modular designs allow capacity expansion without costly infrastructure changes. At the same time, environmentally-conscious merchants can leverage the machine’s reduced emissions and low waste profile to meet regulatory and consumer expectations.

Case studies indicate that users reported a 15% increase in daily throughput and a reduction of operational manpower by approximately 30%, translating into substantial cost savings and improved ROI within the first year of adoption.

One leading medium-scale soybean oil producer reported an increase in oil recovery from 38% to 45% after integrating the latest hydraulic press system. Simultaneously, automated features reduced operator staffing from five to three per shift, yielding a 25% reduction in labor costs. These quantitative benefits underline the tangible impact of hydraulic system innovation.

Additionally, the reduced operational noise and lower maintenance downtime contributed positively to workplace safety and equipment availability, reinforcing overall productivity.

Unlock Enhanced Oil Recovery and Operational Efficiency Today!

Discover how state-of-the-art hydraulic presses can revolutionize your oil extraction process—delivering superior yields, streamlined operations, and sustainable advantages. Contact our experts for a personalized consultation and explore tailored solutions crafted for your business needs.