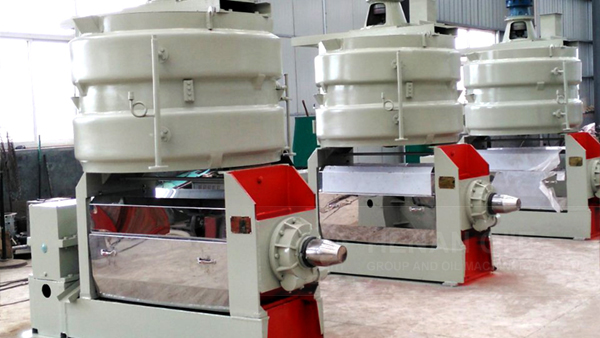

The global vegetable oil industry is witnessing a dynamic transformation driven by increasing demand for diversified edible oils such as soybean, peanut, and canola. These shifts require processing equipment that not only delivers high throughput but also adapts efficiently to varying raw materials and production requirements. The 6YL-185 Spiral Hydraulic Oil Press stands out as a pivotal solution, engineered specifically to address this need for versatility and efficiency in multi-source oil extraction lines.

At the heart of the 6YL-185 lies advanced spiral and hydraulic integration technology. This combination allows for a gentle yet thorough extraction process, significantly improving oil yield by up to 6-8% compared to traditional mechanical methods. The machine features an adjustable pressing chamber and variable spiral pitch, enabling a broad parameter range to optimize pressure and speed according to different oilseed types.

Specifically, the model supports an adaptable screw rotation speed from 15 to 40 rpm and pressing pressure variable between 0.5 to 1.5 MPa. These settings are easily configured to maximize extraction efficiency for diverse raw materials—including but not limited to soybean, peanut, and rapeseed—covering over 12 different types of oilseeds. The hydraulic system ensures consistent pressure application, enhancing oil clarity and reducing sediment content.

Real-world deployments of the 6YL-185 demonstrate its capacity to accommodate complex production scenarios. For example, a large soybean oil producer reported a 12% increase in throughput after upgrading to the 6YL-185, coupled with a 7% gain in oil extraction rate. Meanwhile, a peanut oil processor optimized batch cycles by adjusting hydraulic pressure to accommodate seasonal variations in peanut moisture content without compromising product quality.

Its modular design enables swift reconfiguration, facilitating quick shifts between different raw materials—an essential feature in export-oriented factories that cater to diverse regional markets. This flexibility reduces downtime and lowers operational risks associated with machine incompatibility or suboptimal processing parameters.

As a specialized exporter in the B2B plant oil equipment sector, the manufacturer behind the 6YL-185 offers an extensive global after-sales service network. This network spans over 30 countries, providing localized technical support, training programs, and rapid spare parts distribution. Such coverage is particularly vital given the diverse operational environments and compliance requirements in different markets.

Customers benefit from dedicated account managers who coordinate site assessments and customized installation plans, ensuring seamless integration into existing production lines. Post-sale, regular maintenance advisories and performance monitoring tools are provided digitally to prevent unexpected downtimes, maximizing equipment ROI.

| Feature | 6YL-185 Spiral Hydraulic Oil Press | Typical Competitors |

|---|---|---|

| Adjustable Pressure Range | 0.5 - 1.5 MPa | Fixed, 0.7 MPa Approx. |

| Raw Material Compatibility | 12+ Oilseed Types | Up to 8 Oilseed Types |

| Oil Extraction Efficiency | 84% - 89% | 78% - 83% |

| After-Sales Network Coverage | 30+ Countries | 15-20 Countries |

The 6YL-185’s above-market extensiveness of controllable parameters and robust global service network make it a sensible investment for enterprises looking to future-proof their oil extraction operations.

To explore customized configurations tailored to your specific oilseed processing needs, or to receive detailed technical specifications and case studies, contact our experts now. Unlock the full potential of your production line with a trusted, efficient, and globally supported oil press solution.